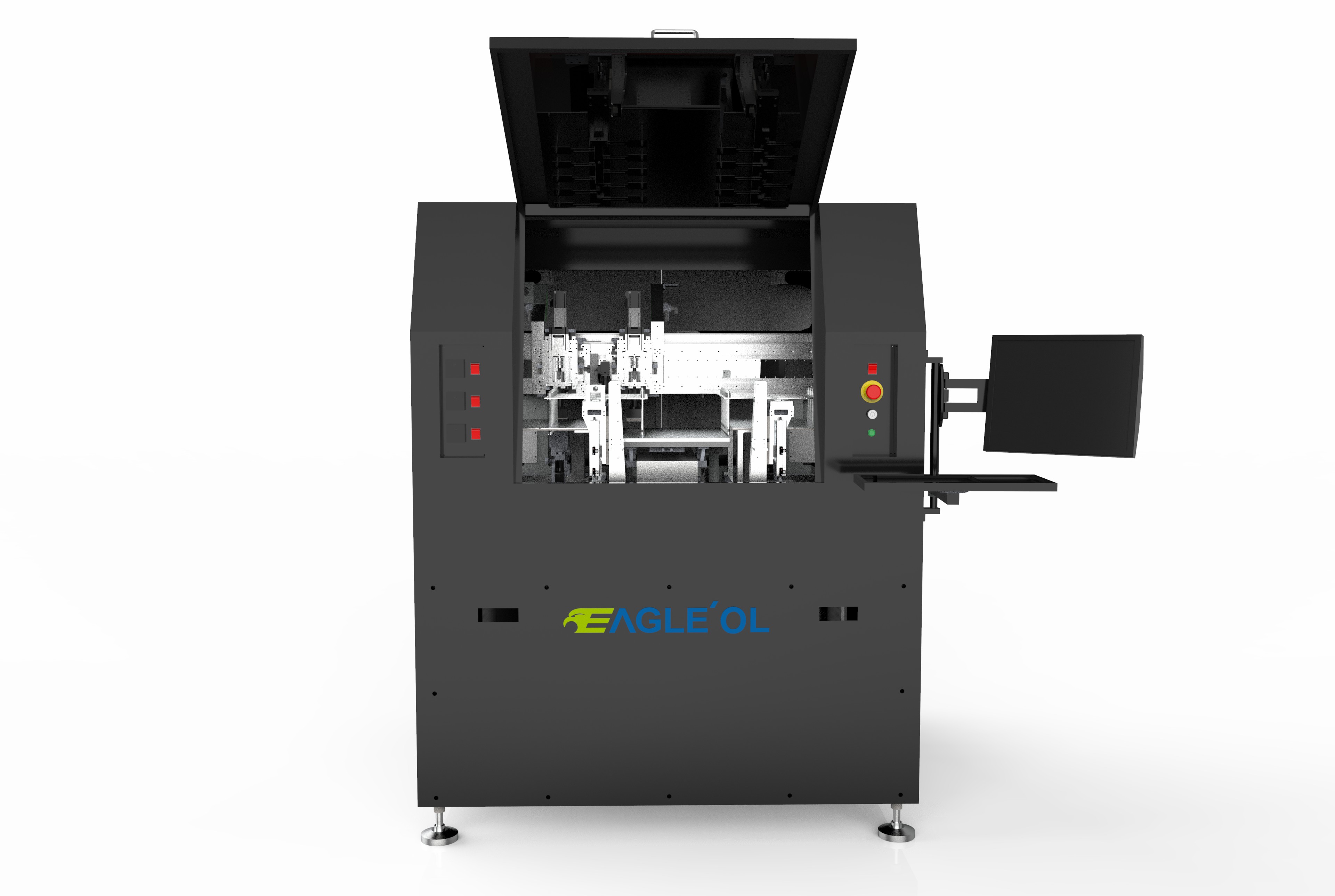

FPC Automatic Reinforcing Machine is an automatic reinforcing machine used to roll materials. It is mainly used to automatically mount roll-type reinforcing materials to FPC board materials through the automatic feeding system.

Technical features

1. FPC board materials has high-precision visual matching function. It can be rapidly programmed through FPC drawings, making it applicable to various FPC reinforcing sheets of different sizes, shapes and thicknesses;

2. CCD can be used to scan, navigate, position and correct mounting materials. At the same time, the software can automatically determine whether absorption materials are good or not and process them by itself;

3. The reinforcing materials are supplied by reinforcing materials. The machine can feed materials automatically. It can be operated for a long time without any intervention. Alarm will be given automatically if there is no material.

4. FPC uses automatic refueling system to change materials. After mounting operations are done, the system will automatically transfer FPC well mounted to the finished work station and take materials from the standby position. This way can reduce person operation. That is to say, one person an operate many machines at the same time.

5. The high-power vacuum adsorption platform can ensure FPC plates to be placed evenly. It also has the heating function, which can ensure that the reinforcing sheets are mounted firmly..

6. High-precision metal suction nozzles which can be heated to 250 degrees are used. It can meet requirements of steel sheets of different sizes and thicknesses;

7. All-Chinese operating system and smart software interface are used to ensure simple operations and easy understanding.

Equipment specifications |

|

Product model | BQ-960 |

Production speed | 1 piece/1 S |

Mounting precision | ±0.05 mm |

Correcting precision | ±0.3 Degrees |

X/Y precision | ±0.01 mm |

Mounting head | Metal suction nozzle |

Size of reinforcing pieces | 2mm×2mm〜50×50mm |

Thickness of of reinforcing pieces | 0.1mm〜0.4mm |

Scope of working table | 260mm×400mm |

Atmospheric pressure | 0.6Mpa |

Vacuum pressure | -0.98kpa |

Transmission model | Linear motor+Servo motor +Ball screw |

Location way | High-precision vision localization+Angle correction system |

Power voltage | 220 V, 50 Hz |

Equipment power | 2000 W (heating the working table and nozzle) |

Machine size | 980mm× 1100mm× 1730mm |

Machine weight | 550 Kg or so |