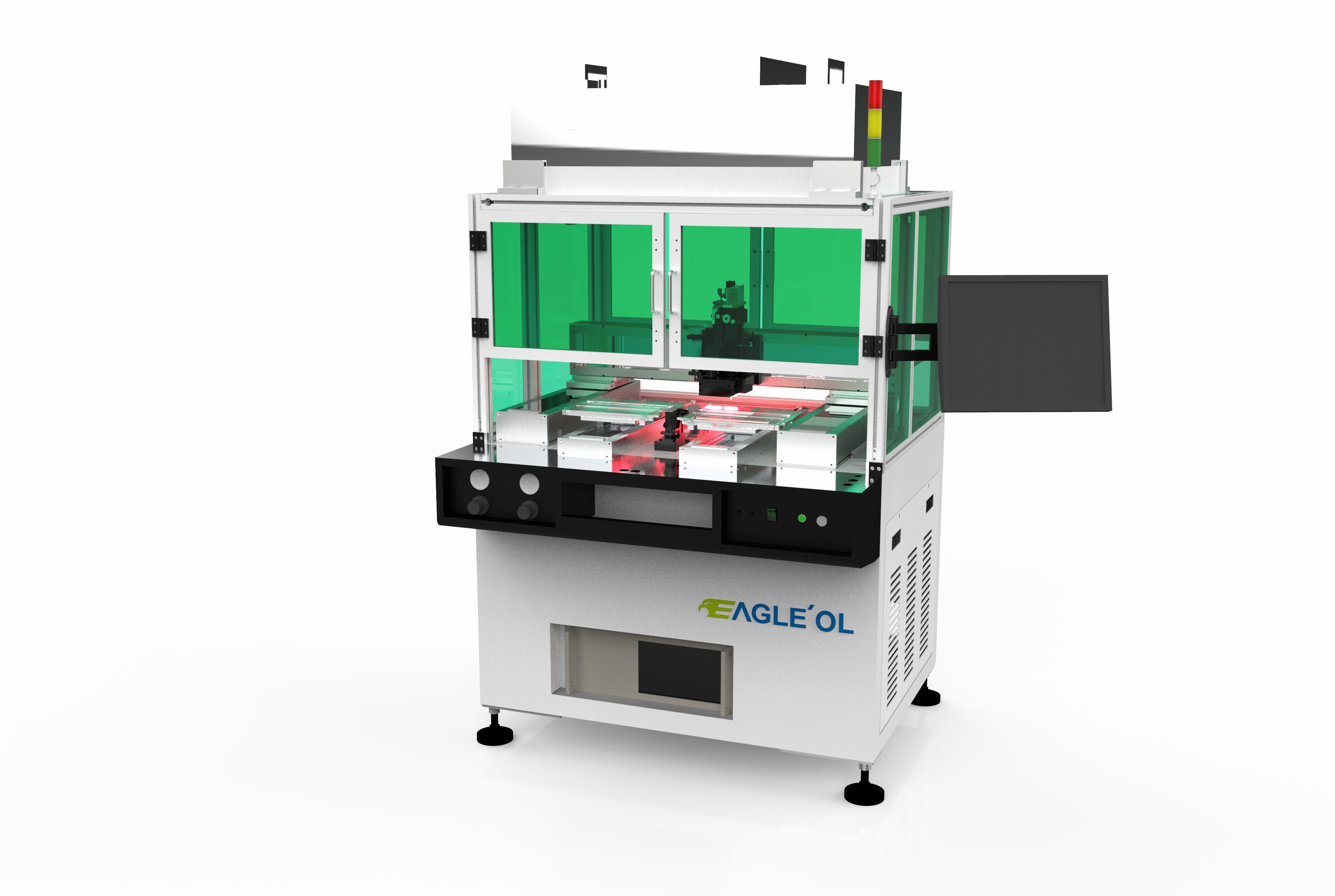

Camera Module Smart Mounting Machine (HOLDER Mounting Machine) is a professional camera module mounting device used for CSP packaging encapsulation technology. It is mainly used to mount the camera module bracket to COMS chips. It can also be used for encapsulation of quartz crystal oscillator chips and iron covers and double-camera module assembly (stand-alone) and other occasions.

Equipment features

1. The high-precision visual aligning system is used to position FPC module, which can meet encapsulation demands of high-quality package.

2. The dust-free design, the high-precision dust-free anti-static transmission module and FFU anti-dust and anti-static device can ensure that all products can be encapsulated under dust-free and static-free state, which can ensure product quality.

3. The design of the automatic left-right dual-working platform can realize non-stop operations of feeding, dispensing and mounting operations. The high-precision and high-efficient smart production can be realized with the aid of the smart vision localization system.

4. The integrated design of dispensing and mounting can realize the production mode of dispensing first and mounting the second, which can greatly save product turnover time.

5. The smart visual correction system is used to pick up and place the products. The visual correction system can be used to adjust the angle and position of products. This way can ensure the mounting precision of all products.

6. The high-precision dispensing system is used. Dispensing needles can be automatically cleaned to ensure the consistency of the dispensing process and the amount;

7. All-Chinese operating system and smart software interface are used to ensure simple operations and easy understanding.

Equipment specifications |

|

Product model | HM- 870 |

Production speed | Painting glue 0.8-1.2 K/hours/ mounting 1.5-1.8K/hours |

Dispensing precision | ±0.05 mm |

Mounting precision | ±0.05 mm |

Rotating precision | ±0.5 degrees |

X/Y precision | ±0.01 mm |

Dispensing equipment | Precising dispensing controller |

Mounting head | Customized suction nozzle |

Transmission model | Servo motor +Ball screw |

Scope of boards | 125mm×80mm |

Scope of mirror base box | 125mm×125mm |

Dispensing pressure | 0.4-0.6 Mpa |

Vacuum pressure | -101kpa |

Location way | High-precision vision localization+Angle correction system |

Power voltage | 220 V, 50 Hz |

Equipment power | 550 W |

Machine size | 1100×980×1660 |

Machine weight | About 420 Kg |