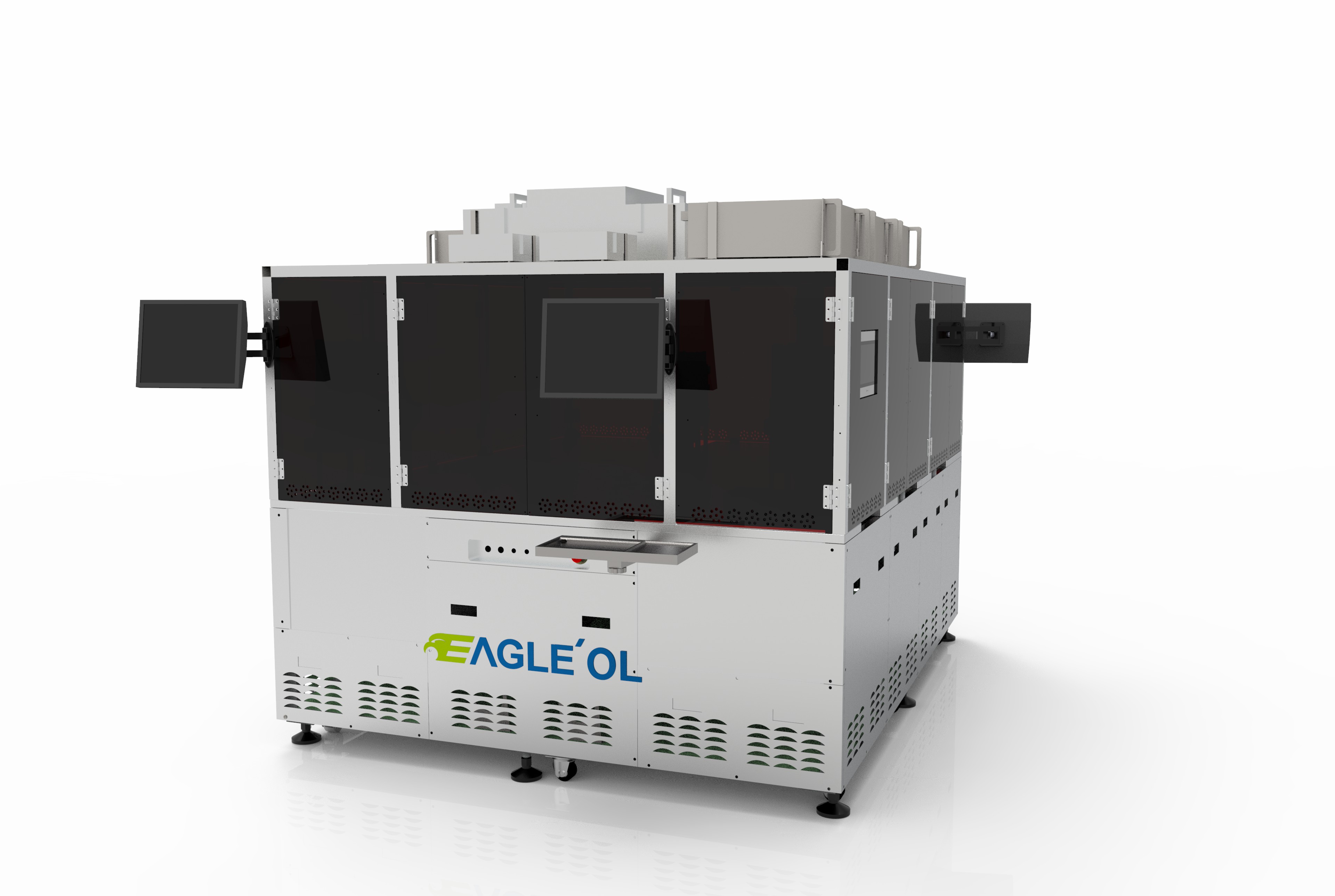

Double-camera Module Integrated Mounting Machine is a kind of non-common substrate dual camera module new integrated assembly equipment specially used in the mobile phone industry. It can realize automatic joint of dual cameras and all operations can be done automatically from inputting materials to exporting finished products. Main processes include automatic loading and unloading operations of all semi-finished products, mounting operation of A and B camera modules, automatic dispensing of Module A and B and the automatic mounting of holders.

The machine adopts the high-precision vision localization system to correct, mount and dispense product angles and positions, which can realize full-automatic continuous loading and unloading operations.

Equipment features

1. The structural design of automatic loading and unloading materials is used. Various semi-finished products and finished products all adopt automatic material loading and unloading modes to realize fully automatic production.

2. Main production processes of the entire machine all use high-precision multi-vision positioning localization system to position, mount and dispense boards or modules, which can meet the requirements of high-quality packaging encapsulation.

3. Double camera up and down can be used to modify products. Different modules can be selected for mounting operations and all kinds of fool-proof operations of products, which can ensure mounting precision of all products;

4. Diversified mounting modes can be used. Clamping claws or suction nozzles can be selected for mounting operations according to actual situations of the product.

5. The two-point dispensing station greatly improves production efficiency. Two kinds of glue can be dispensed at the same time and dispensing stations can be switched at random.

6. Low level alarm system and valve body automatic constant temperature system can ensure liquidity and consistency of fluids.

7. Visual customized dispensing track allows for arbitrary programming of the length, location, and speed of each track segment.

8. The dust-free design, the high-precision dust-free anti-static transmission module and FFU anti-dust and anti-static device can ensure that all products can be encapsulated under dust-free and static-free state, which can ensure product quality.

9. All-Chinese operating system and smart software interface are used to ensure simple operations and easy understanding.

Equipment specifications |

|

Product model | HM-1200C |

Production speed | 1200 pieces/hours |

Dispensing precision | ±0.05 mm |

Mounting precision | ±0.05 mm |

Rotating precision | 0.3 degrees |

X/Y precision | ±0.01 mm |

Dispensing equipment | Precising dispensing controller |

Mounting head | Customized suction nozzle or clamping jaw |

Transmission model | Linear motor+Servo motor +Ball screw |

Assembly line carrier plate | 170mm×70mm |

Lens workpiece tray | 115mm×115mm |

Holder workpiece tray | 224.2mm×194.9mm |

Whole machine pressure | 0.6 Mpa |

Vacuum pressure | -101kpa |

Location way | High-precision vision localization+Angle correction system |

Power voltage | 380V, 50 Hz |

Equipment power | 30KW |

Machine dimensions | 2600×2150×2100 |

Machine weight | About 3200 Kg |