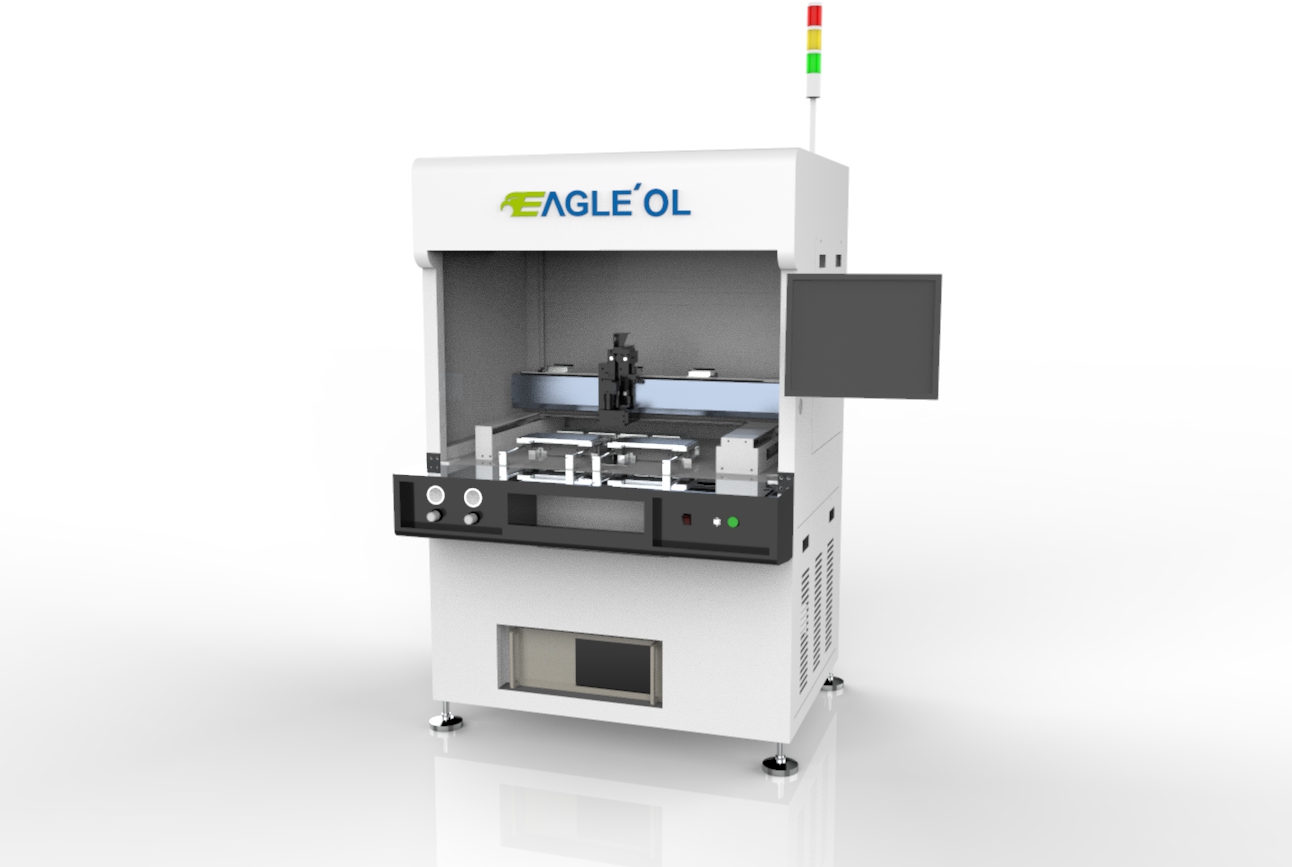

Optical Filter Smart Placement Machine (IR-CUT smart placement equipment) is a kind of high-precision smart mounting equipment used to mount surveillance camera’s optical filters or mobile phone lens to mylar or lens holder.

Equipment features

1. Full visual image aligning system is used. The system can automatically identify the position of mylar and filters. There is no need to accurately arrange products.

2. The high-precision visual alignment system is used to accurately position the mylar. The positioning precision can be up to 0.02 mm.

3. Automatic left-right dual working platform design can realize continuous operation of feeding and mounting material. High-precision and high-efficient smart production can be be achieved. One person can operate more than one devices at the same time, which can effectively save labor;

4. The smart visual correction system is used to pick up and place the products. The visual correction system can be used to adjust the angle and position of products. This way can ensure the mounting precision of all products.

5. All-Chinese operating system and all-Chinese software operation interface are used to simplify the software interface. Operations of the system are simple and easy to understand.

Equipment specifications |

|

Product model | IR-890 |

Mounting speed | 2000 pieces/hours |

Mounting precision | ±0.05mm |

X/Y precision | ±0.01mm |

Rotating precision | ±0.5° |

Mounting head | Double suction head imported rubber suction nozzle |

Mounting scope of optical filters | 10mm×10mm~20mm×20mm |

Mounting scope | 120(X)×250(Y)×2 |

Vacuum standard | -101kpa |

Way of recognition | Optical filter, full-vision automatic decimal alignment of brackets |

Programming method | smart programming software |

Operating system | Windows 7/XP all-Chinese operation interface |

Power supply | 220V, 50Hz |

Power | 800W |

Machine size | 1100×980×1660mm |

Machine weight | About 550 kg |