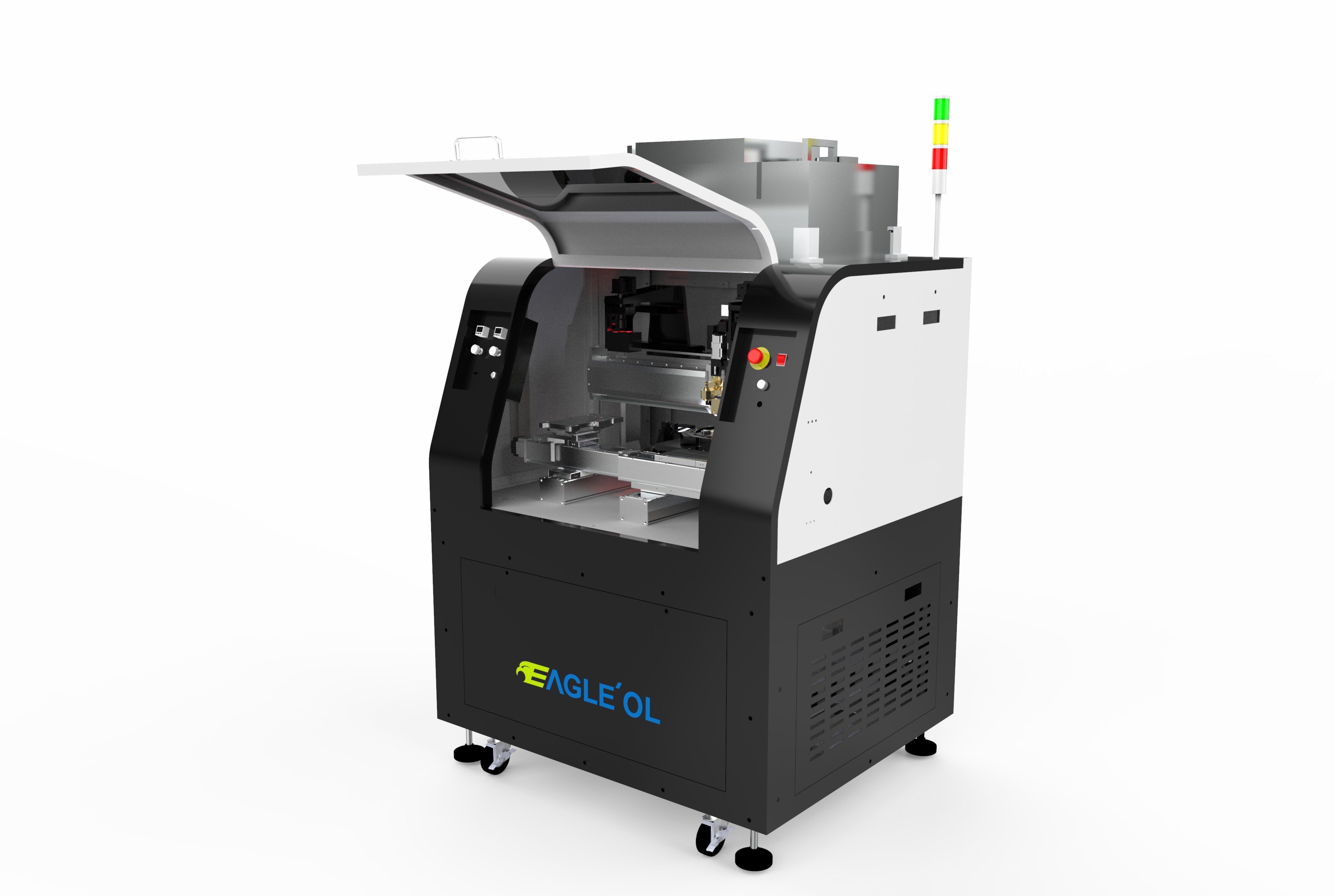

Blue membrane die bonder is a kind of fully automatic mounting equipment for accurately mount chips, glass sheets, ceramic sheets and other chip components for film mounting incoming materials to products. It is mainly used to mount optical communication BOSA optical filters, mobile phone camera module optical filter, ceramic cover plate and other occasions.

Equipment features

1. The system can automatically identify the position of products to be mounted by using the all-region visual counterpoint system. There is no need to place products precisely.

2. The high-precision visual aligning system is used to position membrane chips, which can meet the demands of high quality packaging encapsulation;

3. Blue film feeding device is used. This product is suitable for the blue film incoming materials within 8 inches.

4. The dust-free design, the high-precision dust-free anti-static transmission module and FFU anti-dust and anti-static device can ensure that all products can be encapsulated under dust-free and static-free state, which can ensure product quality.

5. The smart visual correction system is used to pick up and place the products. The visual correction system can be used to adjust the angle and position of products. This way can ensure the mounting precision of all products.

6. It can automatically recognize defective products and do selective operations to products arranged on the working table, which can save cost of the previous operation.

7. All-Chinese operating system and smart software interface are used to ensure simple operations and easy understanding.

Equipment specifications |

|

Product model | IR-980 |

Production speed | 1.3s/piece |

Mounting precision | ±0.03mm |

Rotating precision | ±0.3 degrees |

X/Y precision | ±0.01 mm |

Mounting head | Customized suction nozzle |

Transmission model | Linear motor+Servo motor +Ball screw |

Scope of boards | 120mm×250mm |

Scope of mirror base boxes | 230mm×230mm |

Vacuum pressure | -0.98kpa |

Location way | All-region identification positioning+High precision vision localization+Angle correction system |

Power voltage | 220 V, 50 Hz |

Equipment power | 550 W |

Machine size | 1200×1100×1750 |

Machine weight | About 620 Kg |